A pump is a device which uses to deliver different fluids from one area to other. The pumps are most common all over the world, and they have become a compulsory part of all industries.

There are multiple types of pumps like gear pump, piston pump, centrifugal pump, reciprocating pump. A piston pump is a favorite type of pump from the category of reciprocating pump.

In this article, we will mainly discuss different aspects of the piston pump.

What is a Piston Pump?

A pump that uses a piston to deliver the fluid from one place to another place is known as a piston pump. A piston pump has a piston that reciprocates inside the compression cylinder.

This positive displacement pump has an exterior diameter seal with a piston rod connection. It creates pressure by supplying energy to the liquid being pumped.

This process increases the pressure of the liquid according to requirements.

The piston pump is best for applications that need lower pressures and higher flow rates because it can drain fluids quickly and easily. You can also clean the surface with a piston pump.

Working of Piston Pump

- A piston pump works by moving the piston up and down inside the pump cylinder. A piston pump works in the following way:

- A piston is linked with a shaft that further connects with an electric motor or generator.

- As the electric motor delivers power to the shaft, it turns the piston which starts reciprocating inside the cylinder.

- As the piston moves downward, a vacuum creates inside the cylinder.

- Due to the creation of a vacuum, the pressure inside the cylinder becomes lower than the pressure of the atmosphere or tank.

- Due to this pressure difference, the inlet valve opens, and water starts to enter the cylinder. During this process, the discharge valve remains close.

- As the fluid sucks according to requirements, the inlet valve closes, and the piston starts its upward stroke.

- As the piston moves up (from BDC to TDC), it increases the pressure of the water by reducing the volume of the cylinder.

- As the cylinder's inner water pressure becomes higher than the external pressure, the outlet valve opens, and water is discharged through a discharge valve.

- In this way, the water or other fluid is delivered to the desired location.

|

| piston pump |

Also read: Working of centrifugal pump

Types of Piston Pumps

The piston pumps have the following major types:

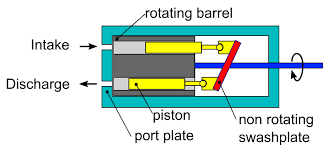

1) Axial piston pumps

These pumps have multiple pistons (usually odd numbers) settled in a circular arrangement within a casing known as a barrel, rotor, or cylinder block.

This block drives to rotate about an axis of symmetry by an integrated shaft that is roughly aligned with the pumping piston.

The axial piston pump uses to power the hydraulics of jet aircraft powered by the main shaft of a turbine engine and is typically depleted in an automotive air conditioning compressor to cool the cabin.

These pumps are designed to meet the restricted space and weight requirements of the automobile's engine compartment and to reduce vibration.

The axial reciprocating motors also use to power small civil engineering machinery like skid loader machines.

2) Radial Pump

The radial pump contains a sequence of pistons in a cylindrical block that surrounds the rotor hub. This block has a rotor, a barrel with a piston, and a shaft.

The rotor moves the fluid in and out of the cylinder. The rotor attaches in an eccentric position inside the casing of the pump.

This rotor also helps the piston to move upward and downward inside the cylinder.

During this motion of the piston, the hydraulic oil is sucked into the cavity of the cylinder and leaves the pump from it.

The pump suction and discharge valves are installed on the central hub.

Each piston connects to the suction valve when it begins to expand and to the discharge valve when it contracts.

These types of pumps supply power to a liquid system by forcing the liquid flow outward. They have high efficiency and reliability.

They have the capability to a high amount of pressure. Therefore, they are used in different types of industrial applications, such as power generation, machinery, and rig testing.

3) Lift or Suction Pump

In this type of piston pump, the upward piston stroke sucks fluid through the valve to the bottom section of the cylinder.

In the piston's downward stroke, fluid passes through the valve and enters the cylinder's upper section.

In the next upward stroke, the piston will discharge the fluid from the upper of the cylinder through a nozzle.

With this type of pump, the air pressure is restricted through the height of the fluid that can withstand the vacuum.

4) Inline Pump

These reciprocating pumps have very high efficiency. The inline pump is best for regulating high flow liquid and water pressure.

It works in the similar way as the bent axis pump but with less rotation capacity.

However, it is a reliable axial piston pump suitable for various applications because it can generate adequate pressure.

Advantages of Piston Pumps

1. These pumps have the capacity to achieve high pressure.

2. These have the capability to transfer abrasives.

3. The piston pumps can also transfer slurries and viscous fluids.

4. These don’t have cavitation problems.

5. They don’t require initial priming.

Disadvantages of Piston Pumps

1. These pumps deliver pulsating flow.

2. The piston pump has a high design.

3. They are bulky.

4. They require high costs for maintenance and initial installation.

5. These types of reciprocating pumps can only handle low flow rates.

Must read: Advantages and Disadvantages of Reciprocating Pump

Applications of Piston Pump

• Hydraulic Pressure Testing

• High-Pressure Cleaning

• Biotechnology

• Water Injection

• Water Hydraulics

• Waterjet Cutting

• Oil Hydraulics

• Drilling Service

• Descaling

• Process Technology

• Energy Saving Fluid Transportation

• Metering Systems

• Fracking

Author Bio

Myself Engineer Waqar and I am a blogger by passion. I did mechanical engineering and Mechanical Boost is my website. I am blogging from 1 year and I have good experience in this field.

No comments:

Post a Comment