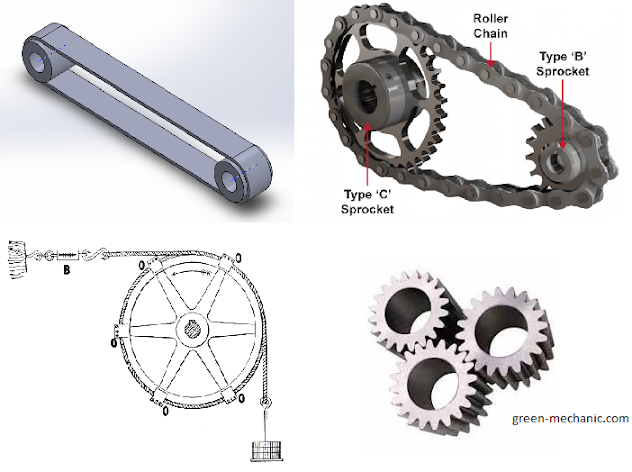

V belt Drive

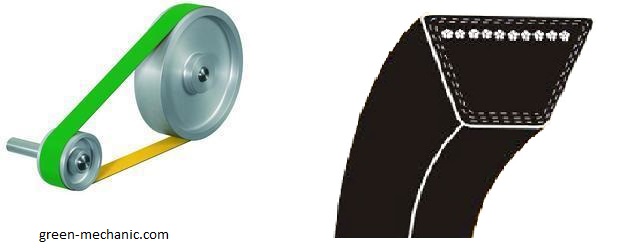

A V belt drive is used for high power; high toque and short distance transmissions. For example power transmission from motor to pumping section of water pump (Dokey pump).

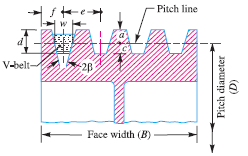

V belt get their names from the shape of their cross section as it looks like the English alpha bet “V”.

Like their cross section shape, the pulley used in v belt drive is also like English alpha bet V.

they can easily cover come the shocks introduce in power transmission system because of greater belt strength and can avoid slipping due to greater belt and pulley friction.

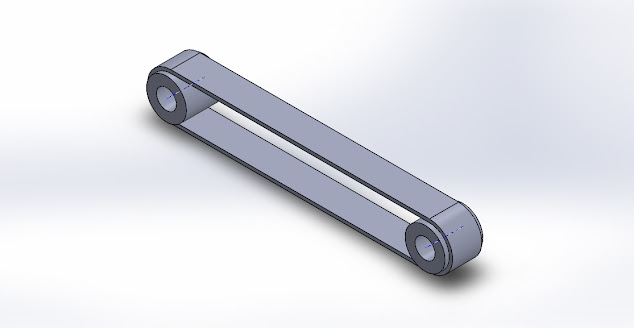

Flat Belt Drive

A flat belt drive is used for moderate power; moderate toque and moderate distance transmissions. For example power transmission from motor to pulley of conveyer belt.

Flat belt get their names from the flat geometry and rectangle shape of their cross section. The pulley used in flat belt drive has a simple cylindrical shape.

They can easily cover come the small shocks introduce in power transmission system but cannot handle high because of moderate belt and pulley friction.

Comparison between Flat belt drive with V belt drive

Flat belts and v belt both are used for power transmission for different mechanism but with same working principles.

In order to know which type of belt can be used for some particular work following is the comparison of flat belt drive with V belt drive.

|

| Flat belt vs V-belt drive |

Comparing power rating of V-belt and flat belt drive

Power rating means the amount of power any mechanism can transfer with effective working.

Power rating of flat belt drive is little less than the V belt drive main due to type of contact between belt and pulley

Velocity Ratio of flat belt and V-belt drive

Velocity ratio means the amount of velocity that can be increased or decreased by any mechanism with effective working.

Velocity ratio of flat belt drive is little less than the V belt drive main due to type of contact between belt and pulley

Difference between performance of V belt and Flat belt

Performance of belt drive means how smoothly a belt can transfer power from driver to driven pulley.Shock absorbing ability of flat belt drive is little less than the V belt drive mainly due to type of contact between belt and pulley

Comparing noise produce by flat belt and V belt drive

Noise is the unwanted sound produce by any mechanism during operation.Both types of belt produce noise but noise produce by flat belt drive is little less than the V belt drive main due to type of contact between belt and pulley

Difference between working life of V-Belt and Flat belt

Life of belt drive is the working hours a belt can provide with effective working.Life of flat belt drive is much more than the V belt drive main due to type of contact between belt and pulley

Comparison of installation of flat belt and V-belt drive

Installation of any belt drive is how easy it is or how much time it require to install or remove any belt from its pulley.Time require to install flat belt drive is little less than the V belt drive main due to type of contact between belt and pulley

Difference between manufacturability of V belt and flat belt drive

Manufacturability of belt drive is how easy it is to manufacture a belt which can work effectively.Manufacturability of flat belt drive is little easy than the V belt drives main due to design of belt.

Cost comparison between flat belt and V belt drive

Cost of the belt drive is how much a belt cost because they are replaced continuously.Cost of flat belt drive is little less than the V belt drive main due to type of contact between belt and pulley.