One of the tasks in designing of any mechanical product like Belt Drive Power Transmission Mechanism is the selection of material for it.

Material selection for the belt drive is the most important task in designing of the Belt Drive Power Transmission Mechanism, as the strength and density of the material will decide the dimensions and working parameters of the product.

Material selection of Belt Drive Power Transmission Mechanism consists of follow steps

1. Product Requirements

2. Material Selection Criteria

3. Available Material Analysis

4. Final Material Selection

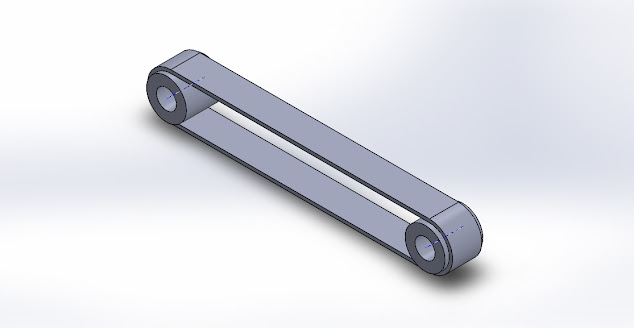

|

| Belt Drive Mechanism |

Product Requirements for Belt Drive Power Transmission Mechanism

Product requirements are based to the working of the product. They are those mechanical, physical and economical properties which are required for the effective working of the product.

For the effective working of the belts following are the mechanical, physical and economical properties which are required.

1. Tensile Strength2. Elastic Modulus3. Fatigue Strength4. Density5. Cost

Tensile strength of belt material will help them to resist against the external load during operation.

Higher the tensile strength of the material higher will be its ability to resist the external load George Murray (n.d).

Elastic Modulus

Elastic modulus of the belts material will help them to resist elongation in belt length under stress.

Higher the elastic modulus of the belt material higher will be its ability to maintain its shape under stress.

Fatigue Strength

Fatigue Strength of the belts material will help them to resist fatigue load during work.

Fatigue loading is the cycling load which happen lathe machine usually during threading process.

Higher the Fatigue Strength of the belt material higher will be its ability to resist Fatigue loading.

Density

Density of belt material means how much weight belt will have I a given dimensions of the belts.

Lower the density of belt material lower will be the weight of the belt and higher the density of the belt material higher will be weight of the belt.

Cost of belt drive

Cost of the belt material will show now much the belt power transmission will cost.

Lower the cost of belt material lower will be the cost of the power transmission and higher the cost of the belt material higher will be cost of power transmission.

Material Selection Criteria for Belt Drive Power Transmission Mechanism

Material selection criteria for belts will involve giving priority to the material mechanical, physical and economical properties based on their requirements.

For giving priority to material mechanical, physical and economical properties number out of 5 will be awarded to them for highest being 5 and lowest being zero.

Following is the priorities giving to the material mechanical, physical and economical properties based on their requirements

1. Tensile Strength

Tensile strength of the belt material is the most important mechanical property required for effective performance of the belt.

As it will define the maximum Tension a belt can take so this property will have 4.5 marks out of 5

2. Elastic Modulus

Elastic modulus is also very important as it high value will unsure that belt will not extend when load is applied on it.

It also effect the maximum tension that can be applied on belt so it will have 4 marks out of 5

3. Fatigue Strength

Fatigue strength is also very important as it high value will unsure that belt will have long life under calculated loading condition.

It also effect the working parameters that can be applied on belt so it will have 4 marks out of 5

4. Density

Density is also very important as its low value will unsure that belt will be light weight.

It also effect the performance of belt so it will have 3 marks out of 5

5. Cost

Cost is also very important as its low value will unsure that belt will be cost effective.

It also effect the overall cost of belt drive so it will have 3.5 marks out of 5

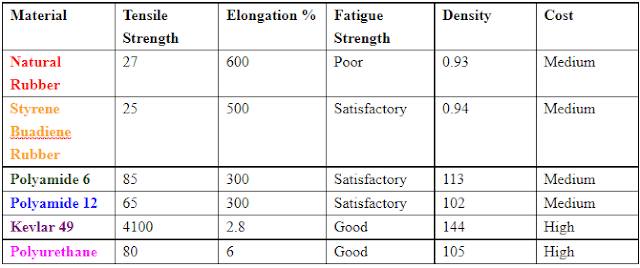

Available Material Analysis for Belt Drive Power Transmission Mechanism

|

| Belt Drive Material and their properties comparison |

Final Material Selection for Belt Drive Power Transmission Mechanism

Final material selection will be done by giving material number between zero to five based on the availability of property present on that material.

Those numbers when multiply with the number that material property got in selection criteria will get the total number for that property.

Material that will have maximum number when total is made that material will be selected.

|

| Belt material selection and material comparison |

From the material selection process Kevlar 49 is selected as the material for belt manufacturing.

No comments:

Post a Comment