Power transfer from primary mover to any mechanism which gives some useful outcome is one of the most common works done in mechanically engineered products.

In order to transfer power form primary mover to any mechanism products like gears, belts, rope and chains are used.

These products transfer power from one place to another and also can provide mechanical advantages in terms of increase speed or torque at output.

From the above mention products belts are one which can be used to transfer power from primary mover to mechanism when primary mover and mechanism is far apart and light weight power transfer mechanism is required.

Belts have the ability to effectively transfer power even when primary power and mechanism are even meters away from each other.

|

| Flat belt vs V-belt drive |

What is a Belt Power Transfer System?

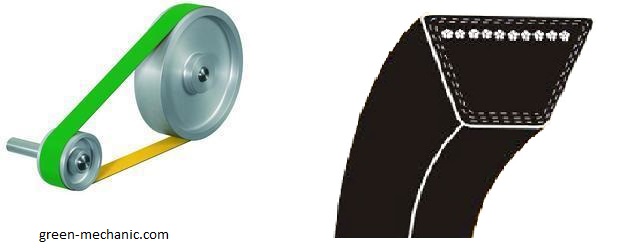

Belt power transfer mechanism consists of at least two pulleys (from which one is attached to shaft of primary mover and second is attached to input shaft of mechanism) and one belt (which stretches between two pulleys).

In belt power transfer system there are three types of belts which are used, one is flat belt drive, second is V-belt drive and third is round belt drive.

What is a Flat Belt Drive?

As their name say flat belts are flat in shape and are usually used when center to center distance between primary mover and mechanism is not more than eight meter.Flat belts are widely used in industry for transferring power in mechanism of machines like bucksaws, silo blowers, sawmill, conveyors, threshers, water pumps, electric generators and balers.

Flat belt derives has been used since 19th century and still they are one of the best option in power transmission systems.

They can be used to transfer high power rating between 500 horse power to 10, 000 horse powers at long distances and high speed.

What is a V-Belt Drive?

As their name says v belts has cross section shape like the English alpha bat V and they are mostly used in those application where the center to center distance between primary mover and pulley is small.

V belt drives has special pulley system on which they are installed for operations and shape of these belts are the same as that of the v belt.

The angle made by the v shape is always between 30 to 40 degrees. Operation range in terms of speed of v belts is in between 300 to 1200 meter per min.

The pulley of the v belts is also shaped like English alpha bat V and this special shape helps the system to grip the belt properly and increase the friction between belt and pulley.

What are some advantages of V Belt Drive?

1. V belts derives are compact in size as they are designed to transfer high power in small distances.

2. The slip between the pulley and belt is almost zero due to which the belt drive for this type is positive

3. There is joint problem in v belts as they are manufactures in special way to make them endless and this make v belt drive smooth

4. V belts has very good life which is usually three to five years

5. V belts are easy to operate and maintain as they can removed and reinstalled easily

6. V belts provide power transfer at very low noise

7. V belts has the ability to absorb the shock of primary mover when machine is initially started

8. V belts can provide very high velocity ratio which is up to 10

9. V belts can be operated in any direction means in it does not matter where is the tight side of the belt.

What are some disadvantages of V belt Drive?

1. As they are design for compactness so they can never be used for long distance power transfer

2. These belts are not as durable as flat belts are

3. Pulley cost is more as compared to others types as they need a special grove for belt placement

4. There low ability to resist the creep limit their use from constant speed application and in timing devices

5. V belt life depends on the temperature under which it operates.

6. V belts has lower speed limit of 5 m/s and upper speed limit of 50 m/s

No comments:

Post a Comment