Power transmission is one of the most comment phenomena which happen in most of the mechanical powered machines.

Power transmission is the transfer of power from primary mover to the mechanism which provides the useful output.

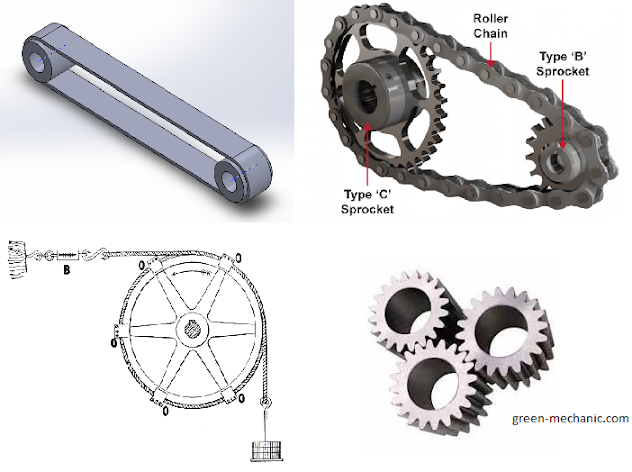

Following are four different types of power transmission methods used in each and every mechanically powered device.

1. Gear Drive Power Transmission System

2. Chain Drive Power Transmission System

3. Rope Drive Power Transmission System

|

| Four Different Power Transmission Methods |

Gear Drive Power Transmission System

This methods of transmitting power using gears is one of most commonly used method in vehicles where power from motor or engine is transfer to the tires using one or more gear sets.

Gear drives are mostly used in those applications where length between the primary mover and driving mechanism is very small and power or rpm value requirement at the output is fixed.

Gears used in gear drives are as follow

1. Spur Gears2. Spur Helical Gears3. Bevel Gears4. Helical Bevel Gear5. Worm and worm wheel

Advantages and Disadvantages of Different Types of Gears

Chain Drive Power Transmission System

Power transmission using chain is one of most commonly used method in vehicles like bicycle and motor bike where power from motor or engine is transfer to the tires using set of chain and sprocket.

Chain drives are mostly used in those applications where length between the primary mover and driving mechanism is large and weight of chain drive done not affect the system.

The power or rpm value requirement at the output is fixed for chain drive power transmission system.

Difference Between Chain Drive and Belt Drive Mechanism in Power Transfer

Rope Drive Power Transmission System

Power transmission using ropes is one of most commonly used method is machines (in which large power is needed to transfer with light weight mechanism) where power from motor or engine is transfer to the tires using set of rope and pulleys.

Rope drives are mostly used in those applications where length between the primary mover and driving mechanism is very large and weight of rope drive done not affect the system.

The power or rpm value requirement at the output is not fixed (slip will not affect system) for rope drive power transmission system.

Belt Drive Power Transmission System

This methods of transmitting power using belts is one of most commonly used method in machines like lathe machine water pump where power from motor or engine is transfer to the tires using one or more belts and pulleys sets.

Belt drives are mostly used in those applications where length between the primary mover and driving mechanism is very large and power or rpm value requirement at the output is not fixed (slip will not affect system).

Belts used in belt drives are as follow

1. Flat Belts2. V Belts

No comments:

Post a Comment