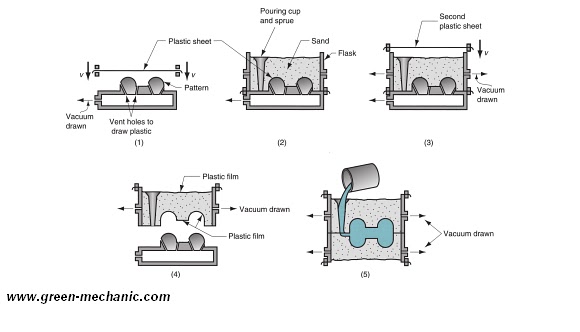

Expandable mold vacuum molding is one which uses vacuum pressure to mold around the metal plate pattern. This process was invented by the Japanese in 1970.

Steps involves in vacuum molding

Step 1

Pattern is made from the metal and have specifically design hole in them to withdraw air to create the pressure. A preheated thin plastic sheet is placed over the patter and held tightly with metal plate because of the vacuum.

Step 2

A special design bucket is placed over the pattern and filled with the sand. All other things like spur, runner, riser etc are made.

Step 3

A plastic sheet is placed over the sand and vacuum is created to held the sand tightly together and so the sand take the shape of the pattern

Step 4

Vacuum is released and bucket is lifted above the pattern

Step 5

Other part of the mold is made is the same way and they attached together to get the one complete mold. Then a hot molten metal is poured into the mold to get the required output.

Advantages of vacuum molding

- No binder is required

- Sand is recoverable

- No effects due to moisture because no water is used in this process

Disadvantages of vacuum molding

- Relatively slow process

- Process cannot be Mechanization

.jpg)

.jpg)

.jpg)