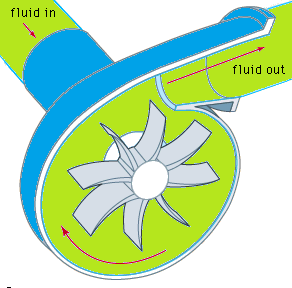

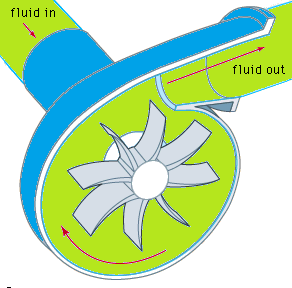

What is Centrifugal pump? centrifugal pump is one which uses the centrifugal force to pump up the water to a certain head.

This type of pump first rotate water using its impeller and then the that rotational motion push water out with a great force.

This force out going water is due to the centrifugal force of rotating water. Centrifugal force try to trough water away in a direction tangent to the water circular motion.

Centrifugal pump have some certain advantages over reciprocating pump. So we have created this comprehensive article about it.

|

Centrifugal Pump Diagram

|

Classification or Types of Centrifugal Pump

Following is division of types of centrifugal pump

1. Type of casing

2. Working head

3. Liquid handled

4. Number of impellers per shaft

5. Number of entrances to the impeller

6. Relative direction of flow through impeller

1. Type of casing

According to the type of casing centrifugal pump have two basic types

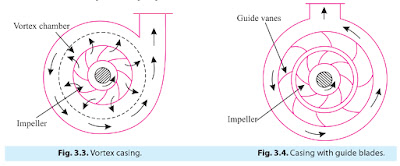

1.1 Volute casing

In order to increase the pressure head, the velocity of water is decrease. It is done by gradually increasing the area of the casing from the impeller out let

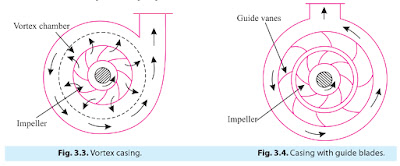

1.2 Vortex Casing

If a circular chamber known as vortex is introduce between the impeller and chamber then the casing is called vortex casing . Its main function is to convert the kinetic energy into pressure energy

2. Working head

Each pump can pump up a water to a certain height so following are the types of centrifugal pump according to the working head

2.1 Low lift centrifugal pump

2.2 Medium lift centrifugal pumps

2.3 High lift centrifugal pumps

Low lift centrifugal pump are capable of working against heads up to 15 m. Medium lift centrifugal pump are basically used against the heads as high as 40 m and High lift centrifugal pumps are used to deliver liquids at heads above 40 m.

3. Liquid handled

According to the type of liquid pumped centrifugal pump is classified into three types

3.1 Pure liquid

When pure liquid is to pumped the centrifugal pump with the closed impeller are used because they have better guidance and high efficiency

3.2 Little impure liquid

When liquid have a little impurity then centrifugal pump with semi open impeller are used

3.3 Liquid with solid matter

When sewage, paper pulp, water containing sand or grit is to be pumped then pump with open impeller is used.

4. Number of impellers per shaft

There are various numbers of impeller that can be diploid on the shaft of a pump and following are the classification based on the number of pumps

4.1 Single stage centrifugal pump

Single stage centrifugal pump is one which has only one impeller attached to the shaft. they are used in place where low head and low discharge rate is required

4.2 Multi-stage centrifugal pump

Multi-stage centrifugal pump is one which has more then one impeller attached to a single shaft. they are used in place where high head and high discharge is required

5. Number of entrances to the impeller

Usually it is consider that pump have only one entrance and one leaving point but there could be more than one and following is classification base upon number of entrances a pump have

1. Single entry or single suction pump

2. Double entry or double suction pump

Single entry also called single suction pump is one in which water is admitted on one side of the impeller.

Double entry or you can say double suction pump is one in which water is admitted on both sides of the impeller; axial thrust is neutralized. They are usually employed for pumping large quantities of water.

6. Relative direction of flow through impeller

Depending upon the direction of the liquid flow centrifugal pump can be classified as follow

1. Radial flow pump

2. Axial flow pump

3. Mixed flow pump

Radial flow pump are one in which regular radial flow impellers are used. Axial flow pump are one in which designed to deliver low head but huge quantity of water. Mixed flow pump are mostly used for irrigation purpose

Centrifugal Pump Parts

We will discuss the centrifugal pump parts by starting from suction of water and will end at delivery of water at reservoir. So parts of centrifugal pumps are as follow.

Suction Side Parts of Centrifugal Pump

Starting the discussion on parts of a centrifugal pump from section side of the pump is important. As most of the important and crucial parts of centrifugal pump are on suction side.

Suction pipe

Pipe which lifts the liquid from the sump and provides it to the pump at the impeller eye is called suction pipe. Suction is made air tight in order to stop the formation of air pocket with in the pump

Strainer

A strainer is attached at that end of the suction pipe which is dipped into the sump. Its main function is to stop the solid particle from entry into the pipe

Foot valve

Just above the strainer there is afoot valve whose function is to prevent the back flow of water when pump is stopped. It is also priming of pump

Impeller

It is just like a wheel with a few number of vanes attached to it. It is mounted on to a shaft which is rotated by an electric motor. There are three main types of impellers used by the centrifugal pump.

Shrouded or closed impeller

Impeller type is which there are vanes with metal cover or vanes with shrouds ends. They have an advantages that they have better guidance and high efficiency but there is one limitation that should be clean and pure

Semi open impeller

In this type of impeller vanes have no crown plates and only have a base plate they have an advantages a over closed impeller that they can pump liquid with little impurities.

Open impeller

In this type of impeller vanes are open from both sides or you can say that they are lacking base plate and crown plate. Their advantages is that they can pump sewerage water, paper pulp and other impure liquid with suspended particles

|

| centrifugal pump impeller diagram |

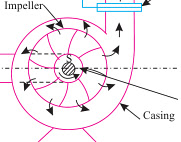

Casing

Impeller of the pump is surrounded by the air tight metal chamber called pump casing. Arrangement is made on casing for the attachment of the suction and delivery pipe. It function is to guide the incoming water toward the impeller and take high kinetic energy water from impeller. Its other function is to convert the kinetic energy of the water into the pressure energy

There are three basic types of casing in centrifugal pump

- Volute casing

- Vortex casing

- Casing with guide blades

|

| centrifugal pump diagram |

Delivery side parts of Centrifugal Pump

Discussing the water delivery side parts of centrifugal pump is also important. They are less in number but are equally important as suction side centrifugal pump parts

Delivery pipe

Pipe which takes the high pressure liquid from the pump and deliver it to the reservoir is called delivery pipe

Delivery valve

Delivery valve is provided at the delivery pipe near the attachment point of pipe and pump. It is use for priming and stopping the back flow of liquid.

Working of Centrifugal Pump

Centrifugal pump work on the principle of centrifugal force. Centrifugal force in one is tried to take away a rotating body from its center of rotation.

In centrifugal pump when a liquid is rotated by the impellers of pump then centrifugal force created will draw away the rotating liquid from the central axis and so a centrifugal head is created which enable the liquid to rise up to a certain level.

Step by step working of centrifugal is given below

Priming of pump

Filling of pump with water so that no air pocket is left in pump is called priming of pump. Priming is done by closing the delivery pipe and fills the whole pump (that is casing, delivery pipe up to valve and suction pipe) with water.

Creating strong suction

A strong suction is needed to start the suction of the liquid from the source. For this purpose delivery valve is kept close and pump is started. Rotating impeller will create a strong suction or vacuum at the eye of impeller.

Creating the normal pressure

Rotation speed of the impeller is increase with the delivery valve closed until it attains a normal speed. With this speed pump establish a normal pressure required to start pumping

Suction of liquid

When pump establish a normal pressure then delivery valve is opened and liquid is sucked into suction pipe and enter into casting through the impeller eye. In casting rotating impeller rotate the liquid and thus create the centrifugal force needed to create the centrifugal head

Delivery

When liquid in the casing attains a specific centrifugal force it is pushed into the delivery pipe and taken to a specific height due to centrifugal head

Continuous process

As long as the impeller of the pump continuous to rotate there will be a suction pressure at inlet and centrifugal head at outlet and the liquid will be transfer from source to reservoir

Closing the pump

When you need to close the pump, first the delivery valve is closed and then impeller should stop rotation. Otherwise there will be some back flow from reservoir

Like every thing else centrifugal pump has their own advantages and disadvantages.

Advantages and Disadvantages of centrifugal pump

Follow are the advantages and disadvantages of centrifugal pump

Advantages of centrifugal pump

- As there is no drive seal so there is no leakage in pump

- It can pump hazardous liquids

- There are very less frictional losses

- There in almost no noise

- Pump has almost have 100 efficiency

- Centrifugal pump have minimum wear with respect to others

- There is a gap between pump chamber and motor, so there is no heat transfer between them

- Because of the gap between pump chamber and motor, water cannot enter into motor

- Centrifugal pump use magnetic coupling which breakup on high load eliminating the risk of damaging the motor

Disadvantages of centrifugal pump

- Because of the magnetic resistance in centrifugal pump there is some energy losses

- Unexpected heavy load may cause the coupling to slip

- ferrous particles in liquid are problematic when you are using magnetic drive.

- This is because particle collect at centrifugal pump impeller and cause the stoppage of pump after some time

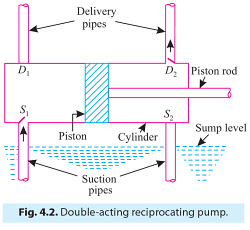

Centrifugal pump vs Positive Displacement pump or Reciprocating pump

There are two main types to pumps available

1. Centrifugal pump

2. Reciprocating pump

The centrifugal pump claims to have following advantages over positive displacement pump. So here is over positive displacement pump vs centrifugal pump section.

1. Because of fewer parts centrifugal pump have less cost than reciprocating pump

2. Also because of fewer parts installation and maintenance are easier and cheaper as compared to reciprocating pump

3. Centrifugal pump have much greater discharging capacity than reciprocating pump

4. Centrifugal pump is compact and small in size and have less weight for the same capacity and energy transfer as compared to reciprocating pump

5. Centrifugal pump performance characteristics are superior as compared to reciprocating pump

6. Centrifugal pump can be used for lifting highly viscous liquid such as paper pulp, muddy and sewage water sugar molasses and oil but reciprocating pump cannot do that

7. Centrifugal pump can be used at high speed without the danger of separation and cavitation whereas reciprocating pump has a danger of separation and cavitation

8. Centrifugal pump can be directly coupled to an oil engine or electric motor whereas reciprocating pump lack this property

9. The torque on the power source is uniform, the output from the pump is also uniform

However, the reciprocating pump have higher efficiency than centrifugal pump and that's why they are still employed for uniform heads and small discharges.

A reciprocating pump has the ability to producing very high pressure as compared to centrifugal and so that’s why they are used for lifting oils from very deep oil wells.

.jpeg)

+(1).jpg)

.jpg)