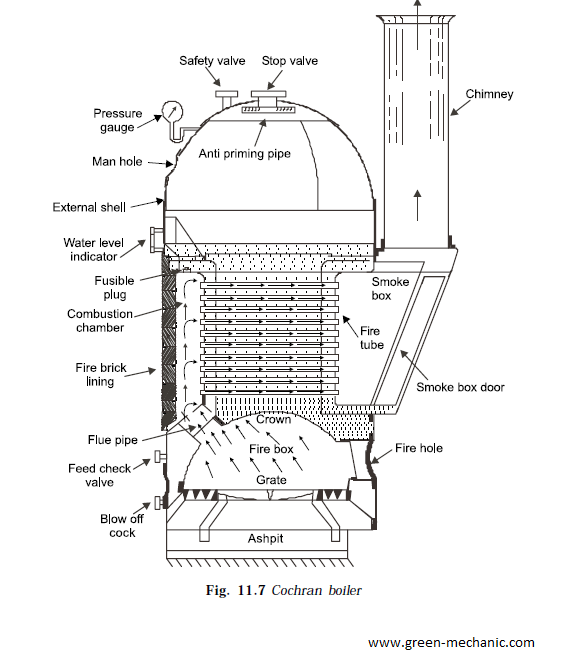

COCHRAN BOILER is a fire tube boiler which is just like the simple vertical boiler with some changes to increase the efficiency of the boiler by increase maximum heating area of the boiler.

Maximum heating are of the Cochran boiler is 10 to 20 times greater than that of the simple vertical boiler. There are two basic changes made in simple vertical boiler in order to make it Cochran boiler.

One is the introduction of cylindrical shell and second is the hemispherical crown.

Hemispherical crown have more strength and give maximum area for the specific mass of the fuel, it also increase the radiant heat absorption.

Parts of the Cochran boiler

Ash pit

Ash pit contain the ashes of the fuel material after the complete combustionGrate

Grate contain the fuel for combustionFeed check valve

Feed check valve is used to check the level of fuel material inside the grateFire hole

Fire hole is used to introduce the initiating fire sparkFlue pipe

Flue pipe take the hot gases from the hemispherical crown and move it toward the combustion chamberFire brick lining

Fire brick lining make sure that heat remain inside and outer side remain coolCombustion chamber

Hot unburnt gases are burnt at combustion chamberSmoke box

Smoke box contain the smoke of burnt gases which come from the fire tubesWater level indicator

It indicates the water level inside the water tankExternal shell

Outer shell which is visible to usPressure gauge

It indicates the steam pressure inside the boilerSafety valve

Use to prevent the establishing of over pressure inside the boilerStop valve

Use to stop the outgoing of steam from the boilerChimney

Take the smoke from the smoke box and throw it out in the atmosphereWorking of the Cochran boiler

All the fuel is place in grate and combustion get started. Hot gases along with some unburnt gases moves from hemispherical crown into the combustion chamber where all the unburnt gases are burn out to produce the heat.Hot gases moves into the tubes there they exchange their heat with the liquid. After moving in the tubes gases in the shape of smoke came out into the smoke chamber from where it moves out through the chimney.

Steam produce is collected into the upper chamber and after the sufficient pressure steam is released toward the use full purpose.

Advantages of Cochran Boiler

- Required minimum area on the floor

- Low construction cost.

- Easy to move from one place to an other

- Because of self-contained furnace. Brick work setting is not necessary.

- All kind of fuel can be used

Disadvantages of Cochran Boiler

- Less steam rising capacity due to design limitation

- Cleaning and inspection is quite difficult due to design

- Limited capacity.

- Limited pressure range

- High head room is required due to vertical design

its a very good explained... i love it

ReplyDeleteThank you for appreciation

Delete