According to the Povindar K (1993) concrete is one of the best construction materials available now due to it’s to take large compressive loads. In the case when the applied load is more than the compressive strength of the concrete, load applied can produce cracks in the concrete column of in any other structure. Due to this crack the other properties of the concrete structure like permeability, durability and strength also start to decrease. To stop this decrease in properties the crack present in the concrete structure has to fix which cost a lot. According to the Kim Van Tittelboom (2008) crack in the concrete structure can be dangerous for the steel placed inside it for the higher strength. Moisture through the crack will enter the concrete structure due to which the steel start to rust, this further decrease the strength of the structure.

According to Salmabanu Luhar (2015) crack and its associated problem in the concrete structure can be solve by using bacteria, bacteria will produce the calcium carbide crystals at the crack surface due to which the crack will be completed filled and will not allow moisture to move inside the concrete structure to rust the steel. Bacterial also fill all the micro cracks present in the concrete structure which further increase the strength of the concrete structure because these micro cracks are some creates bigger cracks upon combining with other small cracks.

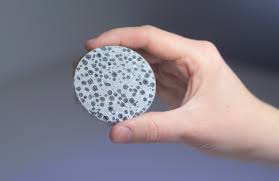

Figure 1 Scenario of crack-healing by concrete-immobilized bacteria (Jonkers 2007).

Types of Bacteria Used for self-Healing Concrete

There are many other types of bacterial which are used to convert a typical concrete into self-healing concrete. Type of bacteria also depends on the type of application and following are some of the application along with the required type of bacteria required for self-healing.

1. As a crack healer

- B. megaterium

- Halomonasrurihalina

- B.pasteurii

- Myxococcus Xanthus

- Deleya halophile

2. For surface treatment

- B. sphaericus

3. As B. apharicus

- Thiobacillus

- B.sphaericus

- Bacillussubitilis

Working Environment

According to Rafat Siddique (2011) the type of bacteria used for this process depends on what type alkaline environment is there in a particular concrete structure because certain bacterial can only live under a certain alkaline environment. According to the Abo El Enein (2013) Genus Bacillus bacteria can survive in the environment with high alkaline because it can form plant seed like spores which are very important to survive such a high alkaline environment. Walls of these bacterial spores are very thick and these spores became active when the concrete structure start to crack and water enters in to the structure through the crack. Spores keep the concrete alkaline value of the range of 10 to 11.5 which is quite suitable for this type of bacteria.

Bacteria Growth

Effectiveness of self-healing concrete depends on the PH level of the concrete. Studies have shown that each type of bacterial needs a unique PH level for proper growth. Bang (n.d) prepared some different nutrient in test tube whose pH ranges from 4 to 12. After that bacterium was introduce in each of them and their growth was observed. Photo calorimeter was used to measure the bacteria sample turbidity. Result show that most of bacteria show proper growth in the pH ranges between 7.5 and 9.0. For Bacillus pasteurii 7 to 9 pH level is consider to best for proper growth and for Bacillus sphaericus 8 to 9 is the best pH level for proper growth. Most of the bacteria which are used in self-healing concrete cannot grow at or above the pH level of 10.

Crack Size

Various studies have been conducted to check the crack size which the self-healing concrete can handle. According to Salmabanu Luhar (2015) study different bacteria can heal different sizes of cracks ranging from 0.87 mm to 300 micro meters.

Effect on Tensile Strength

Test conducted by Peruzzi (2003) show that the tensile strength of the self-healing concrete is better than that of the conventional concrete. Test also show that the tensile strength of self-healing concrete depends on time, more the time lap between manufacturing and test day more was the strength of the self-healing concrete. Test result show that after 3 days there was an increase of 13.75 percent in tensile strength, after 7 days this increment was about 14.28 percent and after 28 days increase in tensile strength was 18.35 percent.

Effect on Compression strength

Peruzzi (2003) also conducted tests to check the compression strength of the self-healing concrete. Test show that the like tensile strength the compression strength of self-healing concrete was more than that of conventional concrete. Results show that increase in compression strength depends on the number of days between manufacturing of concrete sample and test conducted. According to results there was an increment of 30.76 percent in first three days which was increased to 46.15 percent after 7 days and after 28 days it was about 32.21 percent. This increase in compression strength is much more than the increase in the tensile strength of the self-healing concrete.

No comments:

Post a Comment