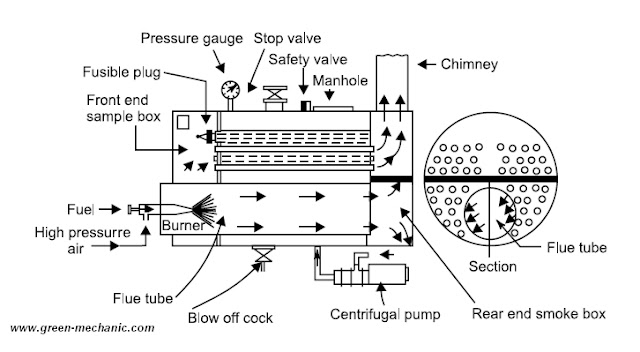

Nestler boiler is a horizontal axis boiler and belongs from fire tube types of boilers. Shell of nestle boiler consist of two thick mild steel plates.

A large number of fire tubes are fitted in between the steel plates. A bigger diameter furnace tube extending from burner end to other end is used for carrying hot flue gases from one smoke box to the other smoke box. At the rear end smoke box chimney is provided for rejection of exhaust gases.

Fuel which is used for the burning is a highly viscous fluid which is firstly heated up to 80 C and then supplied for the burning purpose. Nestler boiler can deliver the steam up to 10-11 bar pressure

You can read our other article to know all about Locomotive boiler Parts, Working and Applications and Cornish Boiler: Parts, Working, Advantages, & Disadvantages

Parts of Nestler Boiler

- Pressure gauge

- Stop valve

- Safety valve

- Manhole

- Chimney

- Rear end smoke box

- Centrifugal pump

- Blow off cock

- Flue tube

- Burner

- Front end sample box

- Fusible plug

|

| NESTLER BOILERS Parts and Working |

Working of Nestler Boiler

Fuel and high pressure air is mixed to produce the air fuel mixture which is burn in o produce the hot gases. Hot gases move through the furnace tube and enter the rear end smoke box of the Nestler boiler.

From the rear end smoke box hot gases enter into the fire tube which is surrounded by the liquid. Hot gases transfer their heat to the liquid and move forward into the front end sample smoke box from there finally hot gases moves toward the chimney from where they are eliminated into the atmosphere.

Steam produce as the result of heat transfer between hot gases and water is collected into the steam chamber above.