CLUTCH AND THEIR TYPES

Transmission system is one of the useful systems in the Automobile vehicle; it helps to transmit the engine power or kinetic energy to the driving wheels. It is an interconnected system of the Clutch, Gear box, Propeller shaft, Differential, Axles and the Driving wheels.

What are Clutch and its functions?

The Clutch is one of the parts of Transmission system in Automobile and help to achieve the movement of it. It is a device or set of number of components which is connected at the end of the engine to the Flywheel used to engage and disengage the driving and pinion shafts.

Its function is to engage and disengage the pinion shaft of the gear to the main shaft or crank shaft of the engine in different power transmission stages, for a smooth movement of torque. It is also the controlling part of the speed of a vehicle with a manual transmission by partially engaging the clutch plate using the clutch pedal.

When the clutch is applied, the total pressure is taken by the pressure plate then the total device moves to back position, it refers the disengage position of the clutch. When we release the clutch, the original position is achieved due to the springs then the driver shaft is engaged to the pinion shaft. It refers to the engage position of the clutch.

What a simple Clutch Consist of?

A simple clutch consists of number of components like Pressure Plate, Disc or Friction plate or Clutch Plate, Fingers, Spacers, Bushes, Levers, etc. These are the main components use in a Clutch construction. These components will vary according to type of Clutch.

What are its types?

According to the speed, efficiency, performance and day by day researches Clutches are of different types, they are

1. Single-Plate Clutch.

2. Multi-Plate Clutch.

3. Cone Clutch.

4. Centrifugal Clutch.

Let us start learn about them individually. Starting with Single-Plate and Multi-Plate Clutch.

Single-Plate and Multi-Plate Clutch:

In the Single-Plate Clutch, there will be only one Plate and it is connected to the Pressure plate adjoining to the Flywheel with the help of bolts and Springs to regain its position. The disc will in the middle of Pressure plate and Flywheel which is free to rotate

Figure 1 Single-Plate Clutch

When the Force is applied on the Clutch Pedal or Pressure Plate, then the disc will get disengage with the Flywheel and no Transmission of Torque takes place between Input (Flywheel) shaft and Output Shaft. In the meanwhile, we change the Gear with help of Gear road then after gearing when we release the force on Pressure Plate, the Disc again Engages with the Flywheel automatically.

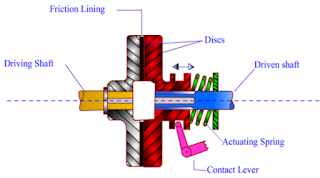

Multi-Plate Clutch

Figure 2 Multi-Plate Clutch

This Working procedure is same in both Single-Plate and Multi-Plate but in Multi-Plate, there are number of Clutch plate which will results a more Torque transmission due the Friction, between the plates and increase in efficiency too when compared to Single-Plate.

Cone Clutch:

Cone Clutch:

Figure 3 Cone Clutch

The sole aim of the Cone Clutch is to transmit the maximum Torque by minimizing the losses in earlier Clutches so in this type; the Plates will be in the shape of Wedge and is called as the Cone. Due to this Wedge or Cone shape, the Torque transmission will be higher and acquires a great efficiency. This type of Clutch is use in the Off-Road Vehicles. Racing vehicles and in Power boats.

Centrifugal Clutch:

Figure 4 Centrifugal Clutch

As we know that, Centrifugal is the acting force tends the body to move away from its centre. There working procedure is same as the normal Clutches. This type of clutches are specially designed for Lower Speeds and Higher Speed Conditions, the Pressure by springs on the plate will be exerted at Low speeds and this pressure force will increases with increase of speed and springs will come backward movement. Due to this backward movement, the driver will feel strain to clutch so to decrease such strain and to maintain the constant pressure force on the plates Semi-Centrifugal and Centrifugal Clutches will exert an outward force on the plates. It makes the springs to engage with the plate even at High Speeds.

Author Biography:

Myself Sai Shankar Rudra from Hyderabad, Telangana State, India. I am a graduated Mechanical Engineer from Sphoorthy Engineering College. I started Blogging from 2016 with Mechanical basics. I write about Mechanical Engineering Subject wise basics and new Technology in it.

Myself Sai Shankar Rudra from Hyderabad, Telangana State, India. I am a graduated Mechanical Engineer from Sphoorthy Engineering College. I started Blogging from 2016 with Mechanical basics. I write about Mechanical Engineering Subject wise basics and new Technology in it.

Thanks for all

ReplyDelete