Design and Development of Automated circle drawer

Aim of this mechanical engineering project is to design and develop an automatic circle drawer which can be used to draw circles of different diameter. This task is a perfect mechanical engineering semester project which can enables students to learn about design an development of product.

Main topics which will be covered int this mechanical project are as follow

- Concept Designing

- Concept Design Selection

- CAD modeling

- Design detail description

- Manufacturing considerations

Concept Designing

Concept Design one

First concept design was the made by keeping in view the regular compasses design. Regular compass have one limitation that it can only draw smalls circles usually used to draw circle on papers. This new concept design has removed this limitation. Its arm can move forward and backward through the rod which enables it to draw big circles. Biggest disadvantage of this concept is that it is very difficult to operate when drawing circle at vertical surface.

Concept Design Second

Second concept design was made by keeping in view the need of drawing the large concentric circles. In this design concept one end of arm is connected with motor and other end is connected a tire. Tire is provided for support. Arm is provided with a slider which enables the design to draw concentric circles rapidly. Disadvantage of this system is that it can only draw circles at horizontal surface.

Concept Design Three

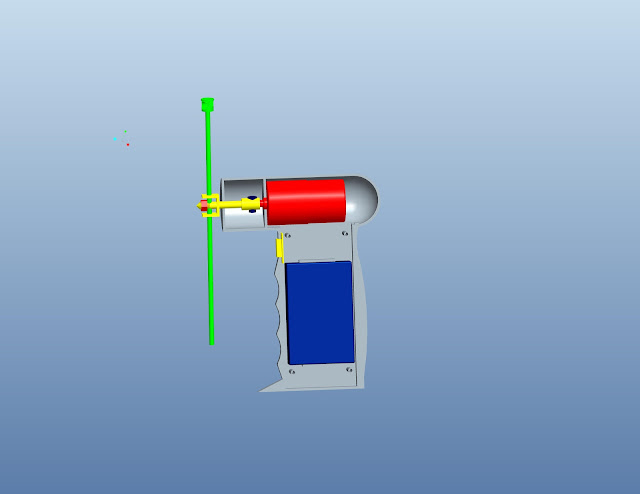

Third concept design was made by keeping in view the need of rapidly drawing concentric circles at any surface. This concept have gun like shape with an arm at its front face. This arm can slide left and right in the cavity of connecting rod which enable it dram circle of any diameter. With the gun like shape it can draw circle at horizontal and vertical surface easily. It will be electrical powered which make it easy to operate.

Concept Comparison

Concept Design One

|

Concept Design Two

|

Concept Design Three

| ||||

Criteria

|

Details

|

Grade

|

Details

|

Grade

|

Details

|

Grade

|

Operations

|

Horizontal operation Only

|

Satisfactory

|

Horizontal operation Only

|

Satisfactory

|

Horizontal and Vertical operation

|

Good

|

Handling

|

Difficult

|

Bad

|

Easy

|

Good

|

Easy

|

Good

|

Working

|

Manual Operation

|

Satisfactory

|

Electrical Power

|

Good

|

Electrical Power

|

Good

|

From the Concept comparison perform above it is clear that the concept design three is the beat design as it provide easy handling, automatic working and operation in all planes.

Introduction

Automatic Circle Drawer Design

1. Electric gear motor

2. DC electric battery

3. Connecting Rod

4. Arm

5. Plastic body

Electric geared motor and battery are enclosed inside the plastic body and arm attached with connected rod are outside of plastic body. One end of connected rod is connecting with the shaft of gear box using a pin and other end contains the arm of the automated circle drawer. Battery provides the DC voltage to the gear motor which rotate at a constant rate and along with it the connecting rod and arm rotates.

Gear Box Design

The gear box of motor have three planetary gears which are used to reduce the speed and increase the torque. In each planetary gear set input is provided to the sun gear which transfers it to three planetary gears. Planetary gears rotate at their own axis and transfer their motion to the annulus ring. Annulus gear of first planetary gear set with the help of front gear plate transfer its motion to the sun gear of the second planetary gear set.

Manufacturing Consideration

Manufacturing Consideration

Table 9 Manufacturing Consideration

Component

|

Material

|

Process

|

Design Consideration

|

Reasoning

|

Body

|

Acrylonitrile butadiene styrene (ABS),

|

Injection

molding

|

2mm uniform wall thickness, draft angle of 1 degree at least, minimum spacing between ribs [3]

|

Injection molding process is selected because it is the easiest and fastest process to manufacture plastic production in mass production case.

|

Motor

|

---------------

|

Purchase

|

----------------------------

|

Available at amazon.com

|

Gears

|

POM

|

Integrated with motor

|

----------------------------

|

----------------------------------

|

Connecting Rod

|

Steel

|

CNC Machining

|

Gear box shaft diameter, Shear strength of material and maximum torque is considered while selecting diameter of rod [4]

|

After selecting diameter of rod, just purchase it form market and then machine it required diameter and make required amendments.

|

Arm

|

Steel

|

CNC Machining

|

Gear box shaft diameter, Shear strength of material and maximum torque is considered while selecting diameter of rod [4]

|

After selecting diameter of rod, just purchase it form market and then machine it required diameter and make required amendments.

|

Comments

Post a Comment